The spiral grinding liner produced by us is applied to the large vertical mill products of Anhui Maanshan Tiangong Technology Co., LTD and CITIC Heavy Industries

- Dec 03, 2023

- Case

Ma 'anshan Tiangong Technology is a large vertical mill and mining magnetic separation equipment R & D manufacturer, focusing on R & D and production of intelligent silo clearing system, vertical mill system, and magnetic separator system, the main magnetic separator products include wet series magnetic separator, dry series magnetic separator, tailings recovery machine, heavy media recovery machine. Tiangong has a long-term technical cooperation relationship with Anhui University of Technology, University of Science and Technology Beijing, Northeastern University and Maanshan Mining Research Institute, forming a good cooperation structure of production, learning and research.

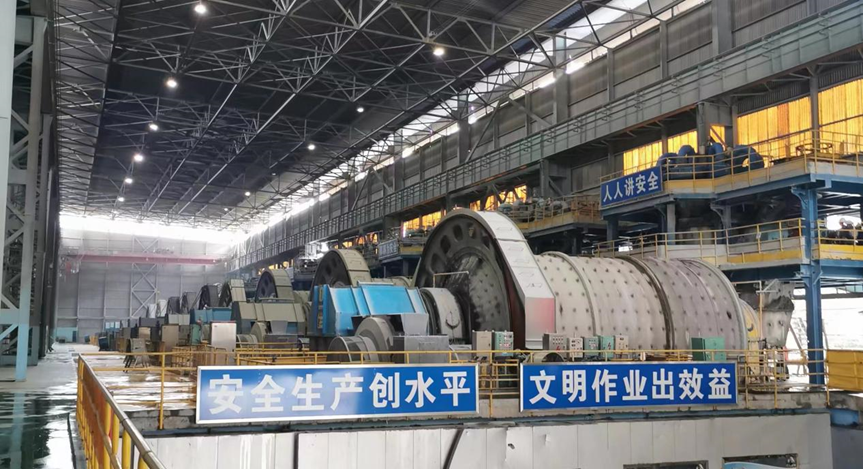

Vertical mill is a collection of fine crushing, drying, grinding, powder selection, conveying in one of the grinding equipment, widely used in cement, building materials, electric power, metallurgy, chemical, mining and other industries of all kinds of solid material grinding and ultra-fine grinding, by a set of grinding device that is the grinding roller and the grinding disc to complete, the material between the grinding roller and the grinding disc is ground into powder.

The movement of the grinding device is driven by the rotation of the grinding disc and the corresponding drive of the grinding roll. The grinding pressure depends on a set of hydraulic devices to press the material of the grinding disc in addition to the weight of the grinding roll. The motor drives the grinding disc to rotate through the vertical reducer, and the solid raw materials enter the center of the grinding disc through the air lock feeding device. Under the action of centrifugal force field, the solid raw materials are thrown to the periphery of the grinding disc and are crushed by the grinding roller repeatedly

Anhui Maanshan Tiangong production of large vertical mill in Jiangxi Copper Gorporation Yinshan mining mineral processing plant has been used, the equipment of a single 2.8 tons of spiral grinding plate produced by our company, the products are mostly used for fine grinding, according to the feedback of the purchaser, the product use effect to meet the requirements of the purchaser.

The material used for spiral grinding liner is Cr15Mo1 high chromium alloy series, the mechanical properties of the product meet the hardness HRC55 ~ 62, the impact value is ≥3J/cm, and it is also the maximum weight of the vertical mill liner produced by our company at present, and the customer satisfaction is very high. The service life is more than 10% higher than that of similar domestic products. At the same time, our company is also to CITIC Weight and a large number of domestic and foreign leading vertical grinding machine equipment manufacturers supply similar products, product quality has been praised by customers.