The application of overflow ball mill and semi-mill liner produced by JCC-Canhu in medium hard ore medium of Dashan mineral processing plant, Jiangxi Copper Corporation

- Oct 16, 2023

- Case

The predecessor of Jiangxi Copper Corporation, Dexing Copper Mine, was first established in 1958 and formally established its business in 1979. Today, Jiangxi Copper Group has become one of the world's top 500 enterprises and one of the largest copper industry enterprises in China, with more than 40,000 employees worldwide and more than 30 billion US dollars in assets.

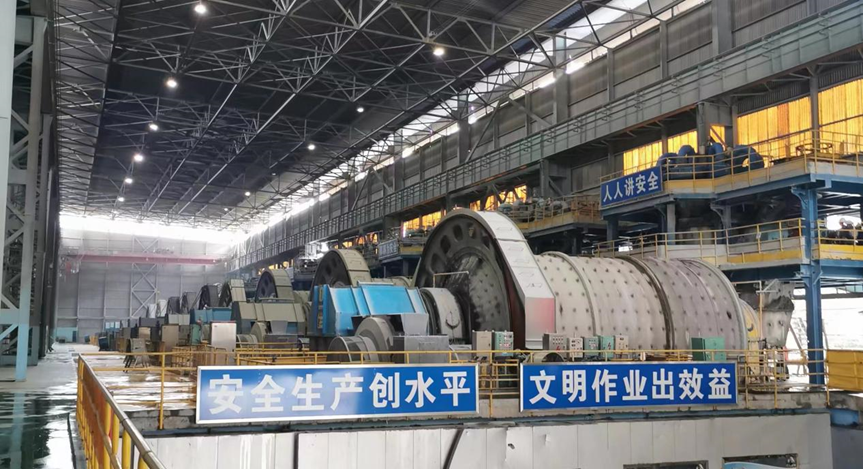

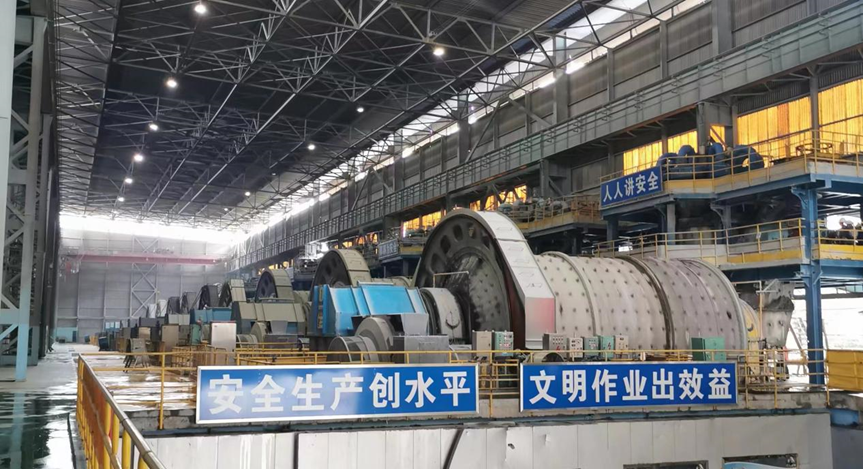

Dashan mineral processing plant, founded in 1988, is one of the main process units of Dexing Copper Mine of Jiangxi Copper Corporation, with a current production capacity of 92,000 tons/day, which is the largest copper ore dressing in China. The 69,500 tons/day system of Dashan mineral processing plant adopts the grinding process of coarse crushing + medium and fine crushing + ball grinding, and the 22,500 tons/day system put into operation at the end of 2010 adopts the grinding process of coarse crushing + semi-automatic grinding + ball grinding.

The mineral processing equipment of Dashan mineral processing plant is configured according to the requirements of large-scale and energy-saving development. After the completion of the capacity expansion project, a coarse crushing transportation system with three 54 "×74" rotary crusers and three steel core transportation tapes as the main equipment is formed. The crushing and screening system with 12 cone crusher, 6 double-layer vibrating screen and 17 single-layer vibrating screen as the main equipment; 69,500 tons/day grinding system composed of 9 sets of 5.5× 8.5m ball mills; The 22,500 tons/day semi-autogenous grinding system is composed of one 10.37× 5.19m semi-autogenous mill, one 7.32×10.68m ball mill and one MP800 stone crusher.

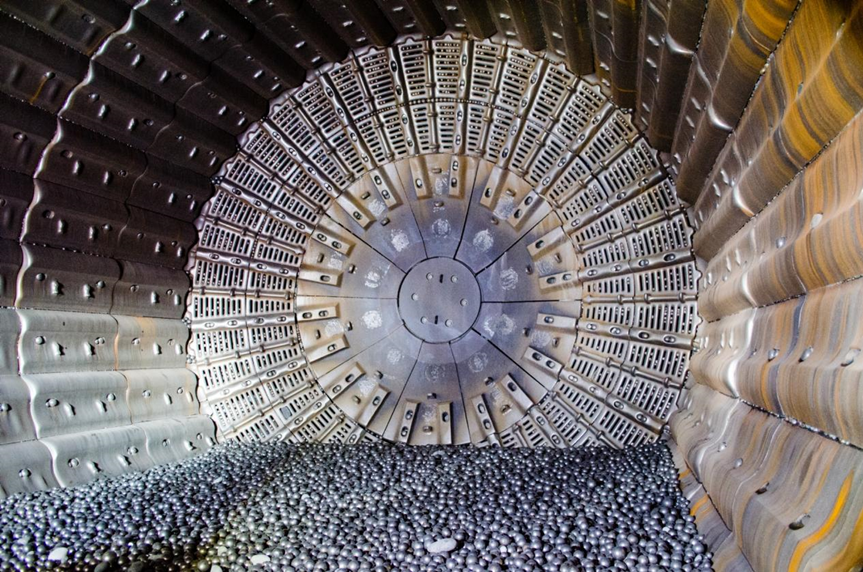

With a diameter of Ф7.32×10.68M overflow ball mill and a diameter of Ф5.5×8.5M overflow ball mill, 1536×525×168.5 and 1835×920×190 size wear-resistant liner produced by us, ZGMn13Cr2 high manganese steel material, In line with GB/T5680-2010 "Austenitic high manganese steel castings" hardness HB180 ~ 220, tensile strength Rm≥735MPa, elongation ≥20% of the standard, expected service life between 10-12 months, according to the customer feedback actual service life is more than 12 months.

Also provided by JCC-Canhu to adapt to 10.37×5.19M semi-mill 1823×515×160 low rib wear-resistant lining, 973×421×325 high rib wear-resistant lining, 70Cr3NiMo alloy steel material, the mechanical properties of the product meet the hardness HRC30 ~ 35, impact value ≥60J/CM2 (no gap), Tensile strength ≥900MPa, the expected service life in 4 months, after the customer feedback after use the actual service life is more than 4 and a half months, far more than the international counterparts of the general standard of 3 months, for customers to save a lot of consumables loss costs, greatly increasing the economic benefits of customers.