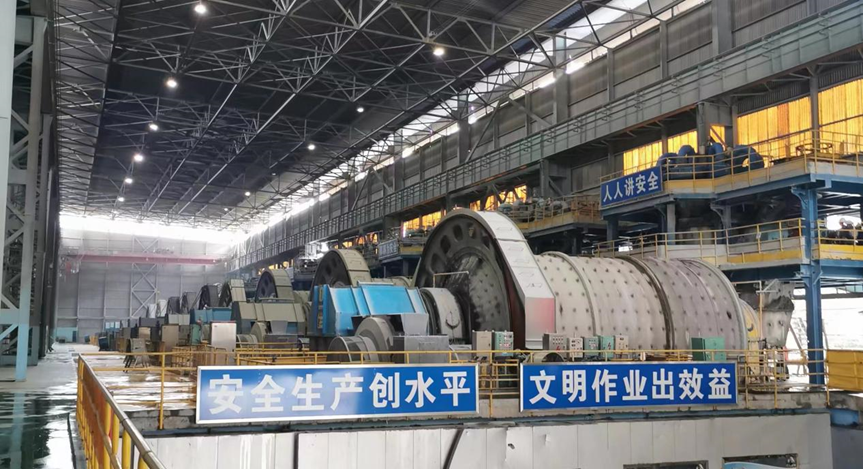

Application of wear-resistant liners produced by JCC-Canhu of gyratory crusher in Dexing Copper Mining of Jiangxi copper Group

- Dec 29, 2023

- Case

Dexing Copper Mine has two stopes, including copper plant and Fujiawu, Chengmenshan Copper Mine, Dashan mineral processing plant, Sizhou mineral processing plant and mine tailing power plant, and 29 sub-units, with more than 16,000 employees. With the most advanced equipment in China, such as electric shovel, automill, flotation machine, belt conveyor, and now the main mine of Jiangxi Copper Corporation, Dexing Copper Mine attracts the world's attention with its scientific management, advanced technology and majestic, spectacular and huge momentum. The copper fine powder produced by Dexing Copper Mine is mainly sent to Guixi base for smelting.

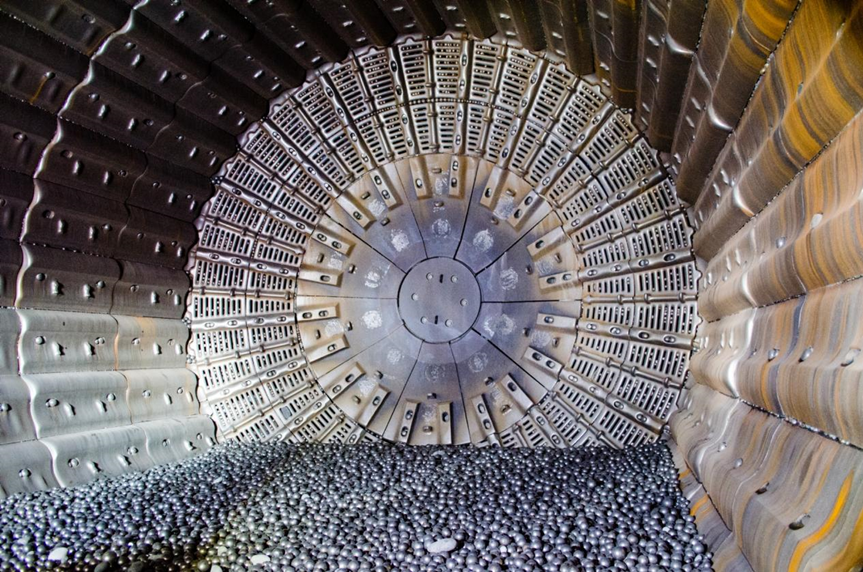

Gyratory crusher is mainly used for raw ore crushing, in the crusher work, the liner is subjected to large impact energy chiseling wear, so high manganese steel strong wear resistance, impact resistance, toughness, corrosion resistance and welding performance, It is widely used in mining, metallurgy, coal, building materials, mining, electric power, railway, iron and steel casting and other industries in a variety of relatively simple structure of impact wear parts casting, in the field of machinery manufacturing has a pivotal role.

At the same time, the liners material of the gyratory crusher is required to have high strength and wear resistance. The rolled mortar liner is made of high manganese steel or reinforced nickel chromium white cast iron, and the broken wall liner is made of high manganese steel. The liner is chipped and worn by large impact energy, and the surface of the high-manganese steel liner can be hardened after being impacted, so the liner is made of high-manganese steel. However, there are many high manganese steel materials or short use cycle, which is that their element ratio is not enough or did not reach the appropriate ratio, then the real reason for the insufficient element ratio is the manufacturer's process casting, some in order to save costs, reduce the input of raw materials, and some of their own low process level.

The 54 "×74" gyratory fixed liner produced by our company, PXF6089 rotary fixed liner, the material is high manganese steel series, the mechanical properties of the product meet GB/T5680-2010 "Austenitic high manganese steel castings" standard, our company's technical personnel continue to study, improve the material element ratio and casting technology, The design service life of these products is 5-6 months, and the actual service life is more than 6 months, which fully meets the use conditions of the field working conditions.