Application of high, medium and low chromium grinding balls produced by JCC-Canhu in hard ore medium in Dashan Concentrator of Dexing Copper Mine, Jiangxi Copper Corporation

- Nov 16, 2023

- Case

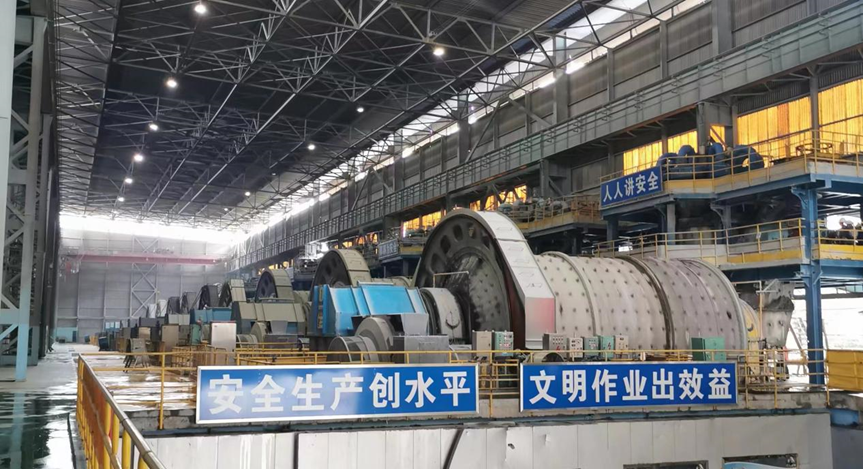

Jiangxi Copper Corporation is one of the world's top 500 enterprises and one of the largest copper industry enterprises in China. Its predecessor, Dexing Copper Mine, was first established in 1958, and its Dashan mineral processing plant was established in 1988. At present, Dashan mineral processing plant has a grinding system composed of 9 5.5× 8.5m ball mills and 1 7.32×10.68m ball mills. The high, medium and low chromium balls used are produced and provided by our company.

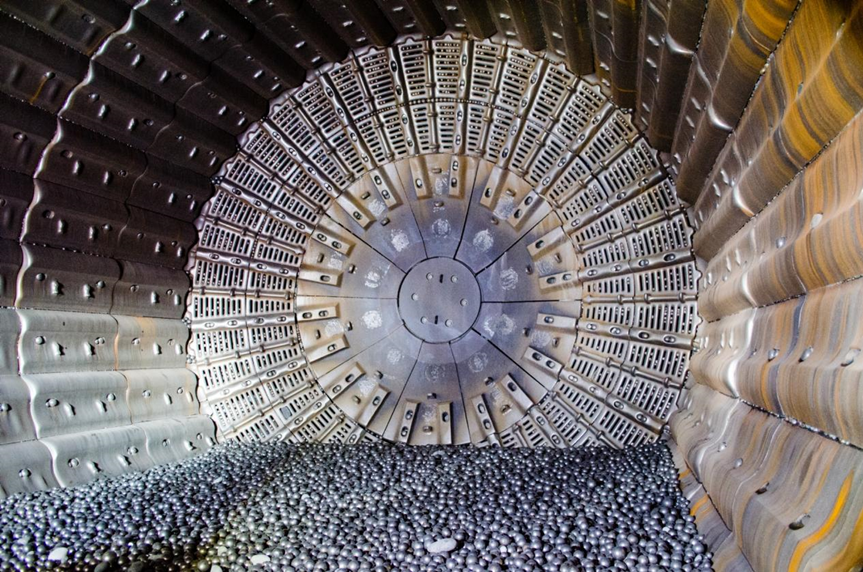

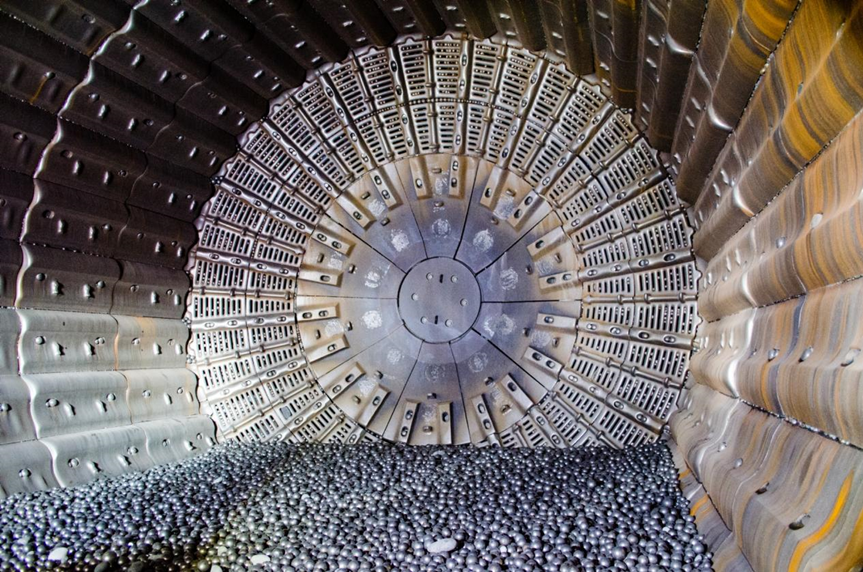

One of the main applications of chromium casting balls is to grind ore in mining operations. Whether it is copper, gold, iron or other minerals, the process of extracting valuable metals from ore involves breaking and grinding the ore into fine particles. Chromium cast balls are commonly referred to as grinding media and are commonly used in ball mills, semi-autogenous mills and crushers to facilitate the grinding process. Chromium cast balls help reduce particle size, promote efficient ore mining, improve beneficiation efficiency and maximize recovery of valuable minerals.

Our chrome cast balls are manufactured using advanced casting technology to ensure stable quality and uniform performance, while the precise control of the composition and heat treatment process ensures the required hardness, toughness and impact strength of the balls. This consistency of quality is translated into reliable and predictable performance, so that different ore media in the German mining industry can achieve consistent grinding results and maintain product standards, the current production of Ф35mm to Φ100mm various specifications of grinding balls, the annual output of 30,000 tons.

In addition to our technical advantages, the chromium cast balls produced by our company also have environmental benefits. The durability and service life of these balls reduce waste generation and resource consumption associated with frequent replacement. In addition, the energy efficiency achieved through the use of chromium cast balls contributes to the reduction of greenhouse gas emissions and carbon footprint. By using these balls produced by our company, Big Mountain Mining Plant mining can combine its operations with sustainable practices and environmental management.

Casting steel ball material is divided into: high chromium steel ball, medium chromium steel ball, low chromium steel ball according to chromium content. Steel balls with chromium content ≥10.0% are called high chromium steel balls, steel balls with chromium content of 3.0-7.0% are called medium chromium steel balls, and steel balls with chromium content ≤3.0% are called low chromium steel balls. The diameter of ¢80 produced by our company is Cr12 grinding ball, the main performance indicators are in line with the casting grinding ball (GB/T17445-2009) : hardness HRC≥58, impact value ≥3J/cm, high chromium ball wear reached 0.7±0.02 on the 5585 ball mill in the Dashan mineral processing plant of Dexing Copper Mine, the feedback after use is very excellent.