A Fortune 500 company

founded in 1960

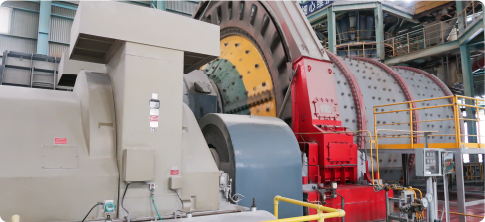

We, Jiangxi Copper Corporation (Dexing) Casting Co., Ltd is a wholly-owned subsidiary of Jiangxi Copper Corporation, Canhu Industry Co., Ltd., the international marketing center of our company is located in Shanghai city , and the JCC-Canhu foundry is located in Dexing city, Jiangxi province. As a large-scale machinery casting enterprise integrating research, production, and operation, the company has 141 professionals, including 13 personnel with senior technical titles and 33 personnel with intermediate technical titles.

The company maintains long-term cooperation with Shanghai Jiao Tong University, Xi'an University of Technology, and conducts effective collaboration to enhance its technical strength and research and development capabilities.

-

44+

Years of Exp

-

186+

Patents

-

500+

Overseas Clients