Application of wear-resistant liners produced JCC-Canhu Foundry in the powder medium of Chengmenshan Copper Mine company which is also a subsidiary company of Jiangxi Copper Corporation.

- Jan 12, 2024

- Case

Jiangxi Copper Corporation is committed to continuously exploring the value of resources, abiding by the commitment of sustainable development, exploring the value of mineral resources with gratitude and awe, and pursuing the harmonious coexistence between man and nature. Diversified business includes copper, gold, silver, lead, zinc, tungsten, rhenium, tellurium and other mining development.

In order to better respond to the digital China strategy, Jiangxi Chengmenshan Copper Mine company closely focuses on the top-level design of the digital JCC Group, comprehensively layout the digital transformation of the mine, and makes full use of advanced technologies such as big data, Internet of Things, 5G and artificial intelligence to create a digital mining platform, a mining vehicle network management and control platform, a three-dimensional visualization platform and five intelligent systems. It has improved the mining whole process equipment and terminal data acquisition access, data integration and application, data-driven and closed-loop with ore flow as the main line, realized intelligent mining and AI+ control of the whole process, and promoted the transformation of open-pit mining from traditional factor driven to data driven and intelligent driven.

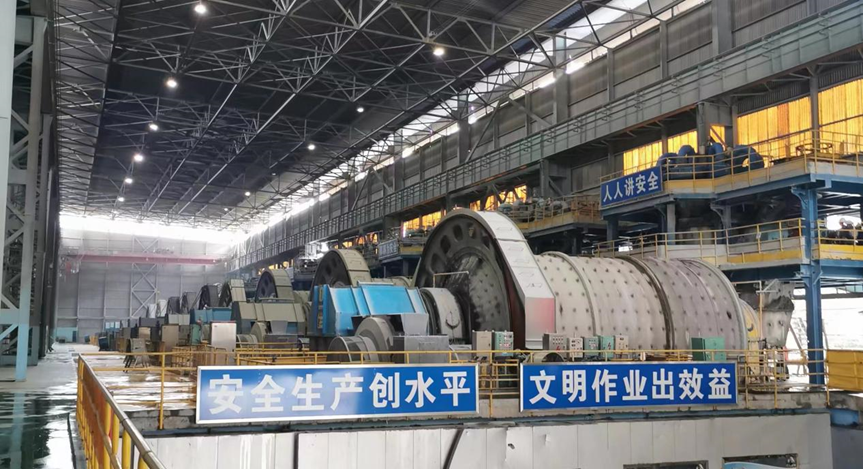

The grinding equipments used by Chengmenshan Copper Mine company are a diameter of Ф3.2×4.5M ball mill, a diameter of Ф4.8×7.0M ball mill, a diameter of Ф5.5×1.8M semi-autogenous mill and a diameter of Ф6.4×3.3M semi-autogenous mill, the 1251×409×150 fine grinding wear-resistant liners used on 3.2×4.5M ball mill produced by JCC-Canhu. The material is ZGMn13Cr2 high manganese steel castings, the mechanical properties of the product conform to GB/T5680-2010 "Austenitic high manganese steel castings" standard hardness HB180 ~ 220, tensile strength Rm≥735MPa, elongation ≥20%, the design service life is 14 months.

In addition, our company produce for the Ф4.8×7.0M ball mill with a size of 750×460×150 wet-resistant liners, the material is ZGMn13Cr2 high manganese steel castings, the standard hardness HB180 ~ 220, tensile strength Rm≥735MPa, elongation ≥20%, the design service life is 9 months; there is a 710×322×250 elevator produced by us for the Ф5.5×1.8M semi-automill, made of 70Cr3NiMo alloy steel. The mechanical properties of the product meet the hardness HRC38 ~ 42, the impact value is ≥40J/CM2 (no notch), the tensile strength is ≥1000MPa, and the design service life is 5 months.

Others the 660×547×285 wear-resistant liners we produced on Ф6.4×3.3M semi-automatic mill. The material is 70Cr3NiMo alloy steel. The mechanical properties of the product meet the hardness HRC30 ~ 43, the impact value ≥40J/CM2 (no notch), the tensile strength ≥900MPa, and the design service life is also 5 months.

According to the feedback of customers after using these products, the life of the alloy steel wear-resistant liner and elevator produced by our company is stable at more than 5 months in the Ф5.5×1.8M semi-autogenous mill and Ф6.4×3.3M semi-autogenous mill, and the life of the wear-resistant liner used in the fine grinding operation of Ф3.2×4.5M ball mill is stable at 14-15 months. With a diameter of 4.8×7.0M ball mill, the wear-resistant liner life is stable at 9-10 months, and the service life is higher than 20% of similar domestic products.