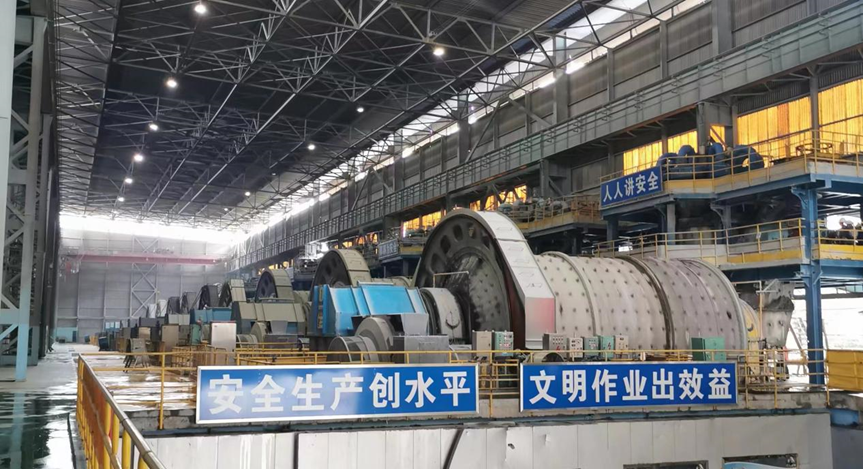

The application of semi-autogenous mill liners and ball mill liners produced by JCC-Canhu Foundry in copper slag and hard ore medium of Fujian Zijin Copper Co., Ltd.

- Jan 03, 2024

- Case

Zijin Copper Co., Ltd. was invested and constructed by Zijin Mining Group Co., LTD., which ranked 284th in Forbes Global 2000 Listed companies in 2023, and completed by the end of 2011 with a total investment of 10 billion CNY. Zijin Copper Co., Ltd. has formed an annual output of 400,000 tons of cathode copper, 18 tons of gold, 400 tons of silver, 1 million tons of sulfuric acid production scale, while by-products such as selenium, tellurium, platinum, palladium, rhodium and other semiconductors, integrated circuits required rare metals, annual output value of more than 30 billion CNY.

Zijin Copper mine is one of the main partners of our company, the use of equipment are gyratory crusher, ball mill and semi-autogenous mill and other mainstream mining equipment, the semi-autogenous mill wear-resistant lining plate and steel ball is the main working parts of the semi-autogenous mill. From the working nature and principle of the semi-autogenous mill, it can be concluded that the wear-resistant lining plate must bear the impact and wear of the steel ball and materials. This requires the wear-resistant liner itself to have enough toughness and impact resistance, so it needs to be balanced according to the situation of the site, from the use of the wear-resistant liner before, their main problem is broken and fracture of the wear-resistant liners. This is caused by insufficient consideration of the working nature of semi-autogenous crushing and insufficient impact resistance of the wear-resistant lining of the cylinder.

Our company in the continuous exploration, continued to carry out the use of wear-resistant liner test work, in the summary and analysis of the previous use of liner, continue to try to choose the same industry semi-autogenous wear liner wear performance is better test, in order to explore the best cost-effective semi-autogenous wear liner.

According to the operating conditions and characteristics of the customer's copper slag (copper slag Mohs hardness 5.4~5.46, density 4.495t /m3) grinding and screening semi-automatic mill, we have targeted to change the tensile strength, yield strength and HV hardness of different parts of the wear-resistant lining plate.

Combined with the mineral distribution, flow direction, particle distribution and the force on the wear-resistant lining plate in different regions of the cylinder, the lifting bar structure of the wear-resistant lining plate in different regions is rationalized, the parabolic curve and drop point of the material are changed, and the running trajectory of the large and small materials and steel balls is more reasonable, which not only reduces the blank hit of materials and steel balls on the lining plate, but also extends the service life of the wear-resistant lining plate. Moreover, the damage of the steel ball is reduced, and the effective impact is increased to improve the crushing efficiency.

JCC-Canhu's strong technical force and scientific experiments continue to improve the wear-resistant liner, and the operation of the semi-autogenous mill has changed well after optimization. The steel ball consumption rate is reduced by more than 10%, effectively improve the service life of the wear-resistant lining plate, the mill wear-resistant lining plate and other accessories produced by our company are in line with the "Austenitic high manganese steel castings" standard, of which the life of Ф5.03×5.0M semi-automill lifter is stable in May to June, and the life of the cylinder lining plate is stable in more than 12 months; With a diameter of Ф5.03×6.4M ball mill cylinder liner plate liner life stable at more than 12 months, 1038×180×190 elevator, the service life can reach 5~6 months, 1038×430×65 wear-resistant liner, the service life can reach 12 months. The 903×482×155 wear-resistant lining plate has a service life of 9 months, and the ore processing capacity per unit can reach 1.31 million tons. This cooperation has improved the overall efficiency of the project and reduced the cost, which has been recognized and praised by customers.