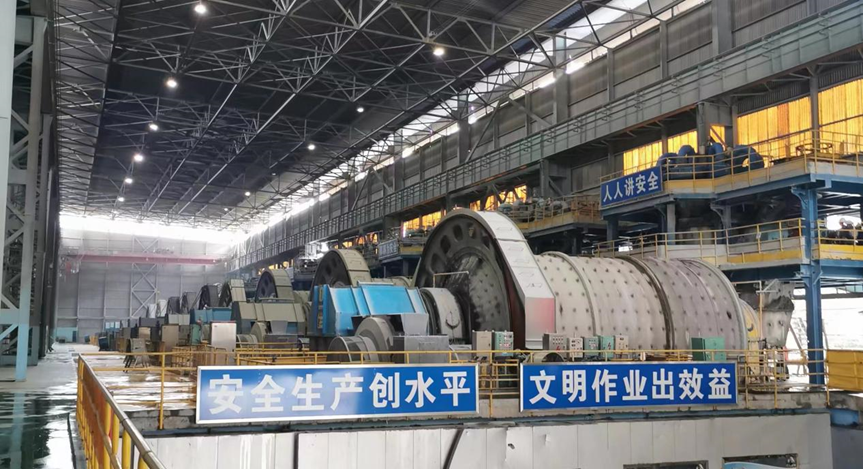

The application of 4.5×4.8M semi-autogenous wear-resistant liners produced by JCC-Canhu in the copper slag medium of Heilongjiang Zijin Copper Mines

- Jan 22, 2024

- Case

Zijin Copper Group is headquartered in Fuzhou, Fujian Province, China. As a subsidiary of Zijin Mining Group, Zijin Copper focuses on copper mining, smelting and processing. Zijin Copper enjoys a high reputation in China and the international market, and is one of the largest copper producers in China. With a series of modern copper mining facilities and smelting plants, the company is committed to providing high quality copper products and solutions. Its product range covers copper concentrate, anode copper, electrolytic copper, copper alloys, etc.

As a responsible company, Zijin Copper focuses on sustainable development and environmental protection. Adhering to the concept of "green mining and green development", Zijin Copper Group is committed to promoting the organic integration of mining business and environmental protection, and continuously improving resource utilization efficiency and reducing environmental impact through advanced technology and innovative processes. Zijin Copper has established a wide range of partnerships in domestic and international markets, cooperating with a number of well-known enterprises around the world to jointly promote the development and innovation of the copper industry.

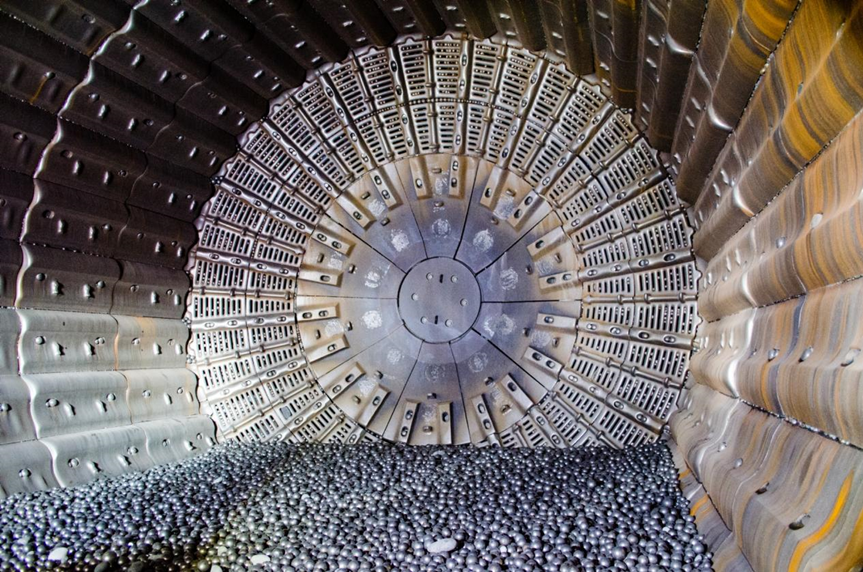

Heilongjiang Copper Mines Company of Zijin Copper Group use a Ф4.5×4.8M semi-autogenous mill, in the grinding condition of copper slag medium, the Mohs hardness range of copper slag is 5.4~5.46, the density is 4.495t/m3. The following two key components are used in the copper slag medium: 1250×256.8×210d lifters, made of 70Cr3NiMo alloy steel. The mechanical properties of the elevator meet the hardness HRC30 ~ 35, impact value ≥60J/CM2 (no notch), tensile strength ≥900MPa. The service life of the elevator is expected to reach 8 months. The 1250×441.3×100 wear resistant liner produced by JCC-Canhu is made of ZGMn13Cr2 high manganese steel castings, which conform to GB/T5680-2010 "Austenitic high Manganese steel castings" standard, the hardness range is HB180 ~ 220, the tensile strength Rm≥735MPa, and the elongation is ≥20%.

This high manganese steel material has excellent wear resistance and impact resistance, which can effectively protect the mill cylinder from the wear of copper slag medium. The service life of the wear-resistant liner is expected to reach 12 months, and the actual service life of the customer is more than 12 months. According to the feedback data of the effect, the lifter life of the Ф4.5×4.8M semi-auto mill is stable at 5-6 months, and the life of the cylinder liner is stable at more than 8 months. In contrast, the life of the cylinder liner of the Ф4.5×4.8M ball mill is stable at more than 12 months. This shows that Zijin Copper Group can extend the service life of the equipment and improve the reliability and stability of the equipment by choosing the suitable wear-resistant liner materials and designs produced and provided by our company. This is of great significance for improving production efficiency, reducing production costs and ensuring continuous production.